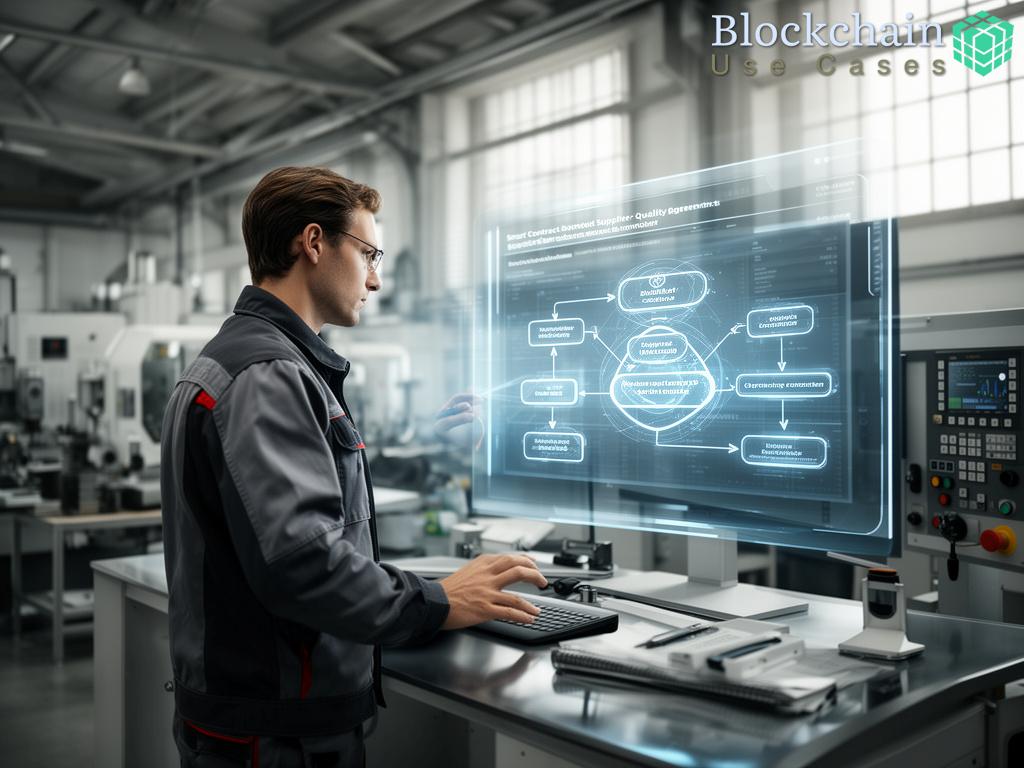

Integration of Smart Contracts into Supplier Quality Management

In an era where digital transformation is revolutionizing manufacturing, smart contracts are emerging as a cornerstone for enhancing trust, efficiency, and transparency in supplier relationships. By embedding quality assurance protocols directly into blockchain-based contracts, manufacturers can ensure that every supplier adheres to predetermined standards without manual intervention. The integration of smart contracts into Supplier Quality Management (SQM) signals a paradigm shift toward automation and verifiable compliance.

Transforming Supplier Collaboration and Compliance

Supplier Quality Agreements (SQAs) have traditionally relied on paper documents or centralized software systems vulnerable to misinterpretation and delayed enforcement. Smart contracts redefine this approach by encoding quality terms, performance metrics, and compliance obligations into tamper-proof digital agreements. This enables automatic execution of clauses, such as payments or penalty impositions, once conditions are verified through Internet of Things (IoT) data or quality inspection reports.

Manufacturers benefit from increased traceability, as every transaction and quality verification is recorded immutably on the blockchain. In turn, suppliers gain credibility through transparent compliance records, reinforcing long-term partnerships built on data-driven trust.

Key Advantages and Comparative Insights

Implementing smart contracts within SQM offers measurable advantages in operational oversight, legal transparency, and real-time analytics. Below is a comparative table highlighting how traditional SQM systems differ from blockchain-integrated models.

| Aspect | Traditional SQM | Smart Contract-Integrated SQM |

|---|---|---|

| Data Transparency | Limited, centrally stored | Fully auditable, blockchain-based |

| Automated Enforcement | Manual validation required | Automatic via encoded rules |

| Risk Management | Reactive | Proactive, with predictive analytics |

| Supplier Accountability | Dependent on human auditing | Immutable record-based accountability |

The following list outlines the core steps and considerations for successful smart contract integration into supplier quality processes:

- Define Measurable Quality Parameters: Identify key quality indicators that can be monitored digitally, such as defect rates, material purity, or timely delivery ratios.

- Develop Contractual Logic: Encode quality triggers, penalties, and rewards into blockchain logic to automate supplier compliance actions.

- Integrate Data Sources: Connect IoT sensors, ERP systems, and inspection platforms to feed real-time data into the smart contract ecosystem.

- Pilot and Validate: Test smart contract models with select suppliers before full-scale rollout to evaluate reliability and performance consistency.

- Monitor and Optimize: Use analytics dashboards to refine criteria and optimize the balance between automation and human oversight.

Driving the Future of Digital Quality Governance

The convergence of blockchain and manufacturing quality management represents a future where accountability is algorithmically ensured. As organizations scale global supply networks, the ability to execute transparent and automated supplier contracts becomes indispensable. By embracing smart contracts, manufacturers not only mitigate risk but also catalyze innovation through trusted digital ecosystems. The transition to smart contract-based SQAs is no longer an experimental concept—it is a strategic imperative shaping the next era of manufacturing governance.

Automated Compliance and Performance Monitoring

As manufacturing ecosystems become increasingly digitized, businesses are shifting toward intelligent contract automation as a means of governing supplier relationships with greater accuracy and reliability. Smart contract-based Supplier Quality Agreements (SQAs) have redefined how compliance is monitored and enforced—moving away from periodic assessments toward continuous, data-driven oversight. This evolution ensures that all suppliers adhere to quality expectations around the clock, enhancing both operational consistency and competitive advantage.

Revolutionizing Oversight through Autonomous Compliance

Traditional quality audits, often dependent on manual reports and human interpretation, leave room for discrepancies and delays in identifying non-conformances. Smart contracts, integrated with blockchain technology, eliminate these uncertainties by transforming compliance tracking into a real-time, automated process. Each transaction or quality checkpoint is registered on an immutable ledger, where rules encoded in the contract automatically initiate pre-defined actions whenever thresholds are met—or breached. This ensures that performance deviations trigger instant alerts, corrective workflows, or even contractual penalties, without the need for human mediation.

Manufacturers leveraging this system are able to maintain uninterrupted transparency, verifying compliance not just at shipment, but across every stage of production. Moreover, the heightened visibility of all parties involved fosters a culture of accountability and trust within the supply chain—essentials in a globally distributed manufacturing landscape.

Empowering Real-Time Performance Analytics

The integration of IoT devices, AI-driven analytics, and blockchain-smart contract frameworks has ushered in a new era of responsive supplier performance management. Data from sensors, inspection systems, and enterprise platforms converge to provide a holistic, tamper-resistant view of supplier performance. Smart contracts autonomously interpret this data to measure quality thresholds, authenticate certification validity, and predict risk tendencies based on continuous inputs.

The outcome is a dynamic compliance ecosystem where decisions are informed by verifiable data rather than delayed paper trails. As a result, manufacturers can instantly identify bottlenecks, forecast potential quality failures, and reward suppliers who exceed performance benchmarks—all while minimizing manual intervention.

Key Areas of Automated Compliance Optimization:

- Continuous Quality Validation: Smart contracts automatically approve or flag products based on real-time inspection data.

- Instant Non-Compliance Response: Automated alerts and contractual responses are triggered when performance metrics deviate from specified standards.

- Predictive Supplier Evaluation: AI-enabled analysis detects early warning signs of quality or delivery risks before disruptions occur.

- Data Integrity and Traceability: Immutable blockchain records guarantee that compliance histories are accurate, auditable, and tamper-proof.

- Performance-Based Incentivization: Smart contracts administer rewards or adjustments tied to verified supplier performance achievements.

By coupling automation with integrity-driven digital records, manufacturers can transition from reactive quality management to proactive and intelligent governance. The synergy of blockchain and smart contracts is not merely a technological enhancement—it represents a systemic evolution in how compliance, trust, and accountability are defined in modern manufacturing.

Data Transparency and Traceability in Manufacturing Networks

As global manufacturing networks evolve into interconnected ecosystems, the need for data transparency and traceability has become a defining factor in determining supply chain resilience and quality assurance. Smart Contract-Based Supplier Quality Agreements (SQAs) are reshaping this domain by integrating verifiable, blockchain-enabled frameworks that eliminate data silos and provide unified visibility across all supplier operations. This technological integration not only strengthens compliance mechanisms but also empowers manufacturers to make data-driven, audit-proof decisions in real time.

Blockchain-Driven Transparency Across Multi-Tier Supply Chains

The implementation of smart contracts embedded in blockchain networks allows every participant—manufacturers, suppliers, and auditors—to access a shared and immutable record of quality transactions. The transparency achieved through decentralized data recording ensures that all stakeholders operate from a single source of truth without dependency on manual reporting systems. Each activity, from raw material sourcing to final component approval, is timestamped, authenticated, and preserved on distributed ledgers.

This level of traceability enables instant verification of every quality event and eliminates opportunities for data tampering or misrepresentation. For instance, if a supplier attempts to modify an inspection report post-delivery, the blockchain automatically rejects any unsanctioned alteration. Therefore, the trust once reliant on human mediation is now algorithmically secured through cryptographic consensus. Manufacturers gain the ability to instantly identify non-conforming materials, while suppliers acquire digital credibility through transparent adherence to contractually encoded standards.

| Aspect | Traditional Traceability | Smart Contract-Enabled Traceability |

|---|---|---|

| Data Recording Method | Manual entries via ERP or paper records | Automated, immutable blockchain ledgers |

| Audit Consistency | Dependent on periodic reporting cycles | Continuous, real-time verification |

| Data Sharing | Restricted and centralized | Permissioned and transparent |

| Error Detection | Post-event identification | Immediate anomaly detection |

Real-Time Traceability for Proactive Quality Governance

End-to-end visibility is the new cornerstone of supplier quality governance. Through smart contract implementation, traceability transforms from a reactive audit tool into a proactive management function. Integrated IoT devices, secure APIs, and AI analytics continuously feed data into the blockchain, establishing a real-time quality mirror of the entire supply chain. This continuous data stream allows for precise monitoring of shipment conditions, production variables, and testing outcomes—each automatically validated against the encoded quality thresholds.

When deviations arise, smart contracts execute predefined actions such as notifying stakeholders, initiating corrective measures, or enforcing penalties. This autonomous governance eliminates latency in communication and ensures that accountability is based solely on verified performance. Moreover, the integration of digital identity frameworks within blockchain ensures traceability down to individual suppliers and even specific production batches. Such granular insight fosters confidence in cross-border collaborations and high-stakes industries such as automotive or aerospace manufacturing, where component traceability can directly influence product safety and regulatory compliance.

Creating a Transparent Ecosystem of Trust and Performance

The evolution of Smart Contract-Based SQAs represents more than operational efficiency—it marks the foundation of a new digital trust economy in manufacturing. The capability to track every contractual and quality element from inception to completion enables organizations to transition from reactive issue management to predictive governance. Data transparency is not merely a compliance measure; it has become an enabler of innovation, sustainability, and cross-enterprise collaboration. As more manufacturers adopt blockchain-driven SQAs, transparency and traceability will serve as competitive differentiators, setting industry-leading standards for quality, accountability, and ethical sourcing.

In essence, by merging automation with incorruptible data structures, smart contracts elevate Supplier Quality Agreements into strategic instruments of business intelligence. The result is a manufacturing future defined by verified integrity, performance-based accountability, and the seamless fusion of technology with trust.

Risk Mitigation and Dispute Resolution through Smart Contracts

In the rapidly evolving manufacturing sector, smart contract-enabled Supplier Quality Agreements (SQAs) have begun to redefine how organizations manage supplier relationships, quality assurance, and operational integrity. As companies expand across global markets, maintaining consistency, mitigating risks, and resolving disputes fairly become essential to uphold brand credibility and supply chain resilience. The integration of blockchain-powered smart contracts offers a groundbreaking solution — one where risk anticipation and conflict resolution are automated, precise, and transparent. This new paradigm eliminates ambiguity, accelerates responsiveness, and establishes a foundation for trusted, data-verified collaboration between manufacturers and suppliers.

Proactive Risk Mitigation in Digital Supply Networks

Traditional approaches to supplier risk management often rely on retrospective evaluations and manual inspections, which can leave room for interpretation and delayed interventions. Smart contracts, embedded directly in decentralized blockchain ledgers, activate a proactive defense mechanism that continuously monitors supplier adherence to predetermined quality thresholds. Every performance metric, compliance record, and delivery confirmation is monitored in real time, triggering automatic procedures when risks or deviations occur. Manufacturers are no longer reliant on post-event reports; instead, risk management transitions into a predictive process, guided by AI-powered analytics and sensor-fed data streams.

This predictive governance model ensures that potential quality failures, late deliveries, or contract violations are detected and addressed before they escalate into financial or reputational losses. Embedded logic within the smart contract can, for instance, suspend payments until a corrective measure is executed or automatically reallocate supply quotas to alternative vendors when contractual conditions are breached. The result is a self-regulating compliance framework that fosters accountability, operational continuity, and reduced dependence on human arbitration. Each stakeholder benefits from an immutable audit trail, offering irrefutable proof of compliance or deviation that can be referenced across internal and external audits.

Redefining Dispute Resolution through Algorithmic Fairness

Disputes between manufacturers and suppliers have traditionally been complex, involving lengthy negotiations, incomplete records, and subjective interpretations of quality outcomes. However, with smart contract integration, dispute resolution evolves into a data-centric process where contractual terms are enforced through transparent algorithms rather than opinion-based judgments. Since each step in the supply chain is timestamped and verified on the blockchain, the root cause of any disagreement becomes easily traceable, reducing the time and cost associated with legal or administrative interventions.

Moreover, smart contracts introduce an autonomous arbitration layer that facilitates instant conflict resolution based on verifiable evidence. When discrepancies occur — for example, a mismatch in material specifications or delivery timelines — the blockchain’s consensus mechanism authenticates data sources and initiates pre-coded processes to rectify or reconcile the conflict. This level of algorithmic impartiality ensures decisions are made on objective grounds, enhancing trust among stakeholders and eliminating the biases often associated with manual dispute handling. In industries where seconds and accuracy can define competitive advantage, such automation mitigates delays, reinforces compliance integrity, and strengthens long-term supplier relationships built on truth and transparency.

Strengthening Financial Integrity and Contractual Trust

Beyond operational disputes, financial discrepancies often pose significant challenges in supplier management, particularly when cross-border transactions or multi-currency payments are involved. Through the use of smart contracts, financial risk is drastically minimized as payment release conditions are tied directly to verified completion criteria. Once sensor data, inspection certifications, or delivery confirmations are registered on the blockchain, payments are executed automatically, ensuring that no party can alter or delay financial settlements. This automation not only bolsters liquidity control but also enhances supplier confidence in the manufacturer’s ability to deliver prompt and transparent compensation.

Ultimately, smart contracts transform Supplier Quality Agreements into instruments of precision-driven governance. The combination of blockchain integrity, predictive analytics, and automated dispute resolution ensures that quality, trust, and accountability are maintained throughout the supply chain lifecycle. As manufacturers continue to digitalize their ecosystems, leveraging smart contracts for risk management and fair arbitration will emerge as the gold standard in operational excellence. By replacing uncertainty with algorithmic certainty, the manufacturing world steps closer to achieving a transparent, resilient, and self-validating supply infrastructure.